Renewable Diesel vs. Biodiesel: What’s the Difference and Why It Matters

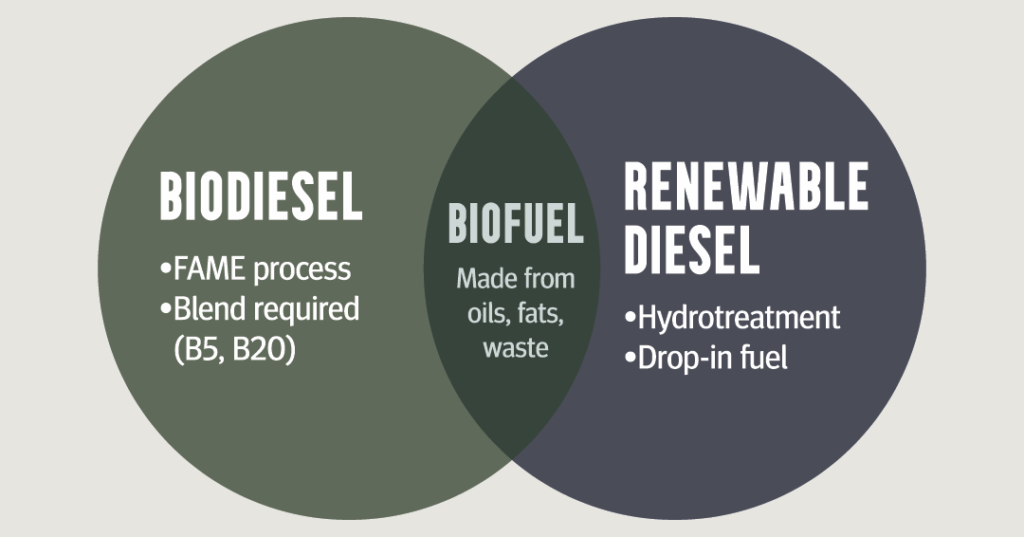

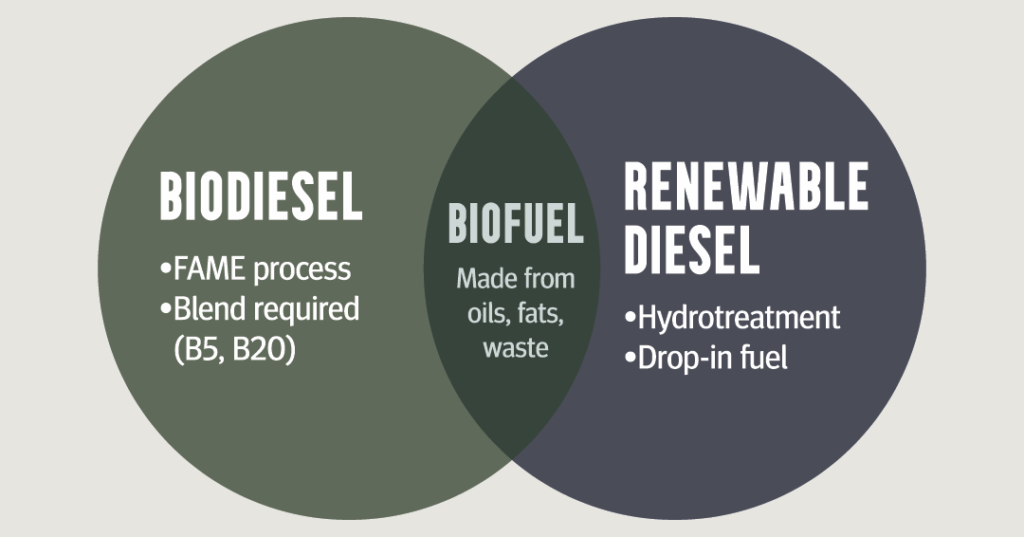

Biofuel is a broad category that includes both biodiesel and renewable diesel. They may come from similar sources, but they perform very differently on the road and deliver different environmental results.

How They’re Made

Biodiesel is made through esterification, resulting in fatty acid methyl esters (FAME) that must be blended with petroleum diesel. Common blends include B5 (5% biodiesel, 95% petroleum diesel) and B20 (20% biodiesel, 80% petroleum diesel).

Renewable diesel (also called Hydrotreated Vegetable Oil or HVO) uses hydrotreatment to create fuel chemically almost identical to petroleum diesel. It’s a true “drop-in” fuel that works in any diesel engine.

Real-World Performance

These chemical differences translate into practical impacts. Biodiesel blends can cause fuel filter clogging, have shorter shelf lives, and create cold-weather issues, especially at higher blends. Some fleets need more frequent maintenance, such as fuel filter changes.

Renewable diesel performs like petroleum diesel in all conditions without infrastructure changes, engine modifications, or seasonal adjustments.

Environmental Impact

Both fuels use similar feedstocks: used cooking oil, animal fats, soybean oil, and other organic waste. However, renewable diesel generally delivers greater greenhouse gas reductions (up to 65% lower than petroleum diesel) because of its efficient production process and no fossil fuel blending requirement.

Why This Matters for Freight

When evaluating a carrier’s sustainability claims, the fuel type affects both environmental and operational outcomes. A carrier using B20 biodiesel is making progress but faces different limitations than one running renewable diesel as a direct replacement.

So when a carrier mentions switching to biofuel, it’s worth asking: Which one? Understanding which type a carrier uses helps separate real sustainability progress from vague promises.

You May Like

A. Duie Pyle Named TMSA Trailblazer Award Winner!

2022 was a big year for our expansion across the region! That was highlighted by the opening of three new facilities across the Commonwealth of Virginia. This venture was no small undertaking, as the locations

Cheers! A. Duie Pyle is Now Offering Next-Day Service and Freeze Protection to Alcohol Distributors Throughout the Northeast.

The Northeast U.S. is a bustling region – and not just on the roadways. Densely populated and home to some of biggest & best cities in the world for sports, entertainment and dining, it is