CUSTOMER PROFILE

One of the largest privately held independent distributors of building materials in the country distributed from locations in the Northeast and Southeast regions. The customer handled distribution through private fleets located at two distribution centers in Pennsylvania and fulfillment centers in VA, MD, NJ, NC, and GA. These fleets were comprised of straight truck flatbed units, single & tandem axle tractors, and a combination of different flatbed trailers.

ORIGINAL CHALLENGE

The customer was faced with deteriorating service levels and customer dissatisfaction due to the combined challenges of driver hiring and retention within their NJ facility. A lack of clearly defined performance standards also led to a distinct reduction in driver productivity and fleet utilization. Pyle provided a competitive proposal and commitment to improving the reliability and efficiency of the delivery operation in NJ by converting their private fleet to a managed dedicated fleet supported by the Pyle enterprise.

Results

- Despite the recruitment challenges facing the Northeast employment market, within 30 days A. Duie Pyle was able to fully implement the first phase of the operation with an eight driver fleet.

- Pyle’s operating team was able to improve service levels to over 99% on time, create real time visibility through enhanced technology, and stabilize the driver turnover almost immediately

- By providing professional, highly trained, customer focused drivers and assuming the human resources and management responsibilities, A. Duie Pyle’s solution allowed the distributor to focus on their core competencies and growth strategies

- Within two months of operating the distributor’s NJ fleet, the customer assigned Pyle operating responsibilities for their larger fleet in MD.

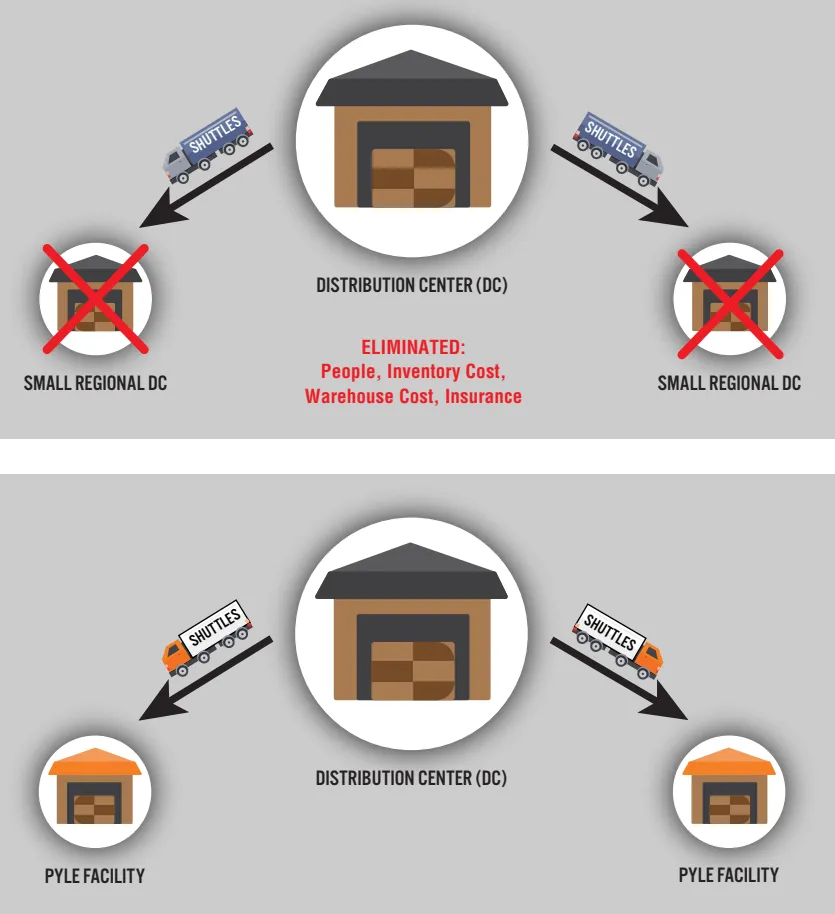

Pyle initially identified the customer’s limited number of product lines and SKUs in comparison to most distributors; most of their fulfillment centers carried the same products to allow their fleets to deliver within a day of an order being placed. There were also nightly shuttles needed for transfers from their PA Distribution center. Due to A. Duie Pyle’s experience and existing infrastructure of service centers and warehouses within the distributor’s delivery footprint, Pyle’s solutions design team suggested a final-mile relay strategy and provided a new route design. This route design involved having their main distribution center in PA loading multi-stop trailers, by route and stop sequence, destined for their NJ and MD customers. These trailers were then shuttled overnight to Pyle facilities in NJ and MD for final-mile delivery the next morning by locally domiciled drivers.

CONTINUOUS IMPROVEMENT PROCESS

PHASE I – INTRODUCING THE FINAL MILE RELAY PROCESS

Having made considerable improvements in just a few months time, both leadership groups continued to hold bi-weekly conversations on the performance of the fleets to uncover even greater efficiencies. This consistent collaboration, combined with the enhanced understanding of the customer’s operational dynamics, key performance priorities, and nuances enabled Pyle’s team to recommend changes to the existing supply chain model.

ORIGINAL CHALLENGE

The customer was faced with deteriorating service levels and customer dissatisfaction due to the combined challenges of driver hiring and retention within their NJ facility. A lack of clearly defined performance standards also led to a distinct reduction in driver productivity and fleet utilization. Pyle provided a competitive proposal and commitment to improving the reliability and efficiency of the delivery operation in NJ by converting their private fleet to a managed dedicated fleet supported by the Pyle enterprise.

Results

- Despite the recruitment challenges facing the Northeast employment market, within 30 days A. Duie Pyle was able to fully implement the first phase of the operation with an eight driver fleet.

- Pyle’s operating team was able to improve service levels to over 99% on time, create real time visibility through enhanced technology, and stabilize the driver turnover almost immediately

- By providing professional, highly trained, customer focused drivers and assuming the human resources and management responsibilities, A. Duie Pyle’s solution allowed the distributor to focus on their core competencies and growth strategies

- Within two months of operating the distributor’s NJ fleet, the customer assigned Pyle operating responsibilities for their larger fleet in MD.

Pyle initially identified the customer’s limited number of product lines and SKUs in comparison to most distributors; most of their fulfillment centers carried the same products to allow their fleets to deliver within a day of an order being placed. There were also nightly shuttles needed for transfers from their PA Distribution center. Due to A. Duie Pyle’s experience and existing infrastructure of service centers and warehouses within the distributor’s delivery footprint, Pyle’s solutions design team suggested a final-mile relay strategy and provided a new route design. This route design involved having their main distribution center in PA loading multi-stop trailers, by route and stop sequence, destined for their NJ and MD customers. These trailers were then shuttled overnight to Pyle facilities in NJ and MD for final-mile delivery the next morning by locally domiciled drivers.

RESULTS

- Through Pyle’s assets and network in the NYC metro region, the distributor was able to eliminate the significant costs associated with operating an additional fulfillment center for their NJ and NY (and NYC) deliveries, while improving the speed and service to their customers in this area.

- Through cost savings in facility lease costs, inventory holding costs, and taxes, the customer was able to consolidate their work-force and prioritize other growth opportunities. Pyle provided a competitive transportation proposal to alleviate the issues and liabilities associated with running a fleet in the Tri-State area and lowered cost per delivery by over 40%.

- As an added benefit, by eliminating cross-dock operations, damages to bulky, high cost products were reduced considerably.

ROUTE OPTIMIZATION AND DIVING DEEPER

The Pyle team continued to probe and discover new opportunities to improve the client’s network. Through on-site meetings and virtual operational review calls, Pyle was able to develop an optimization plan for this distributor based on the fleet analytics collected. As is typical with many fleets, the traditional routing of deliveries were based on static days of the week combined with the every-day last minute adjustments needed based on customer emergencies or product availability issues. Pyle engineering and operations teams noted that smaller shipments were being routed to the outer limits of the delivery areas involving a much higher per shipment transport cost relative to sales revenue. Pyle’s engineering team then presented a plan to optimize the delivery areas for their PA, MD and NJ fleets which resulted in even greater efficiencies.

ROUTE OPTIMIZATION AND DIVING DEEPER

The Pyle team continued to probe and discover new opportunities to improve the client’s network. Through on-site meetings and virtual operational review calls, Pyle was able to develop an optimization plan for this distributor based on the fleet analytics collected. As is typical with many fleets, the traditional routing of deliveries were based on static days of the week combined with the every-day last minute adjustments needed based on customer emergencies or product availability issues. Pyle engineering and operations teams noted that smaller shipments were being routed to the outer limits of the delivery areas involving a much higher per shipment transport cost relative to sales revenue. Pyle’s engineering team then presented a plan to optimize the delivery areas for their PA, MD and NJ fleets which resulted in even greater efficiencies.